Tin Zinc Plating (SnZn)

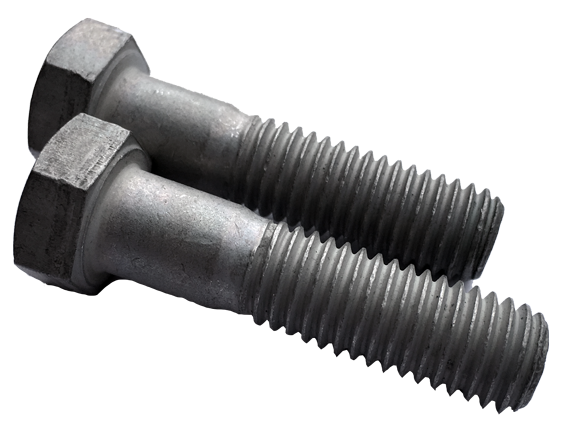

Plating Technology’s experience, commitment to quality, and investment in the latest equipment has earned us an industry-wide reputation for providing high quality finishes at very competitive prices. Our tin-zinc plating services, recommended for use on fasteners and other electrically conductive components used in corrosive environments, exhibits such high corrosion resistance that it routinely surpasses 1500 hours when subjected to ASTM B-117 salt spray testing.

Our fully automated barrel plating equipment applies a uniform finish. Environmentally friendly, the process uses a trivalent chromium passivate to form a corrosion resistant, electrically conductive, and weatherproof coating that withstands even the harshest, sulfur-enhanced environments. The finish also exhibits excellent lubricity, ductility, and solderability, even after months of storage.

Able to handle quantities from prototypes to large scale production runs with 1–5 day lead times, our tin-zinc plating services are suitable for parts used in transportation, construction, mining, and marine applications, and meets the requirements for many auto manufacturer specifications. Our ISO 9001 and ISO 17025 certified facilities are equipped to handle the needs of the most demanding applications.

To learn more about our tin-zinc plating services read below, or contact us today to find out how we can help you with your application.

Benefits & Limitations

Fully automated processing equipment

No hexavalent chromium

Both tin and zinc are environmentally friendly

System plates directly onto hardened surfaces

System has excellent throwing power resulting in relatively uniform thicknesses in deep recesses

Excellent lubricity

Superior ductility allows for secondary bending and crimping while maintaining high corrosion resistance

High corrosion resistance, routinely surpasses 1500 hrs to ASTM B-117 when our trivalent chromium passivate (Corroguard) is applied

Does not form voluminous white corrosion products

Excellent solderability even after months of storage

Demonstrates good resistance to sulfur enhanced atmospheres

Where is Tin-Zinc used?

> 1000hrs of corrosion resistance

Aircraft

Appliances

Automotive

Construction fasteners

Electrical connectors and fasteners

Firefighting equipment

Marine equipment

Mining Industry

Railway equipment

Refuse equipment

Transportation segment (busses, semis, light truck )

These are just a few examples, please inquire for additional information.

Plating Characteristics

Appearance Improvement

Chemical Resistant

Close Tolerance

Corrosion Resistant

Electrically Conductive

Lubrication

Nonreflective

Protective

Weather Proofing

Production Volume

Specialty Production Shop

Prototype

Low Volume

Small Run

High Volume

Large Run

Long Run

Large Scale Production Volume Run

Typical Lead Times Available

Minimum ~ 1 Day

Maximum ~ 5 Days

Equipment

Barrel

Automation Capabilities

Computer Controlled Process

Robotic Load/Unload/Transfer

Testing Ability

X-Ray

Atomic Absorption

Salt Spray

Adhesion

Torque and Tension

Edymag

Specifications

Honda

HES D 2003-05

Ford

WSE M1P93 A-1, A-2, A-3, A-4

WSS M1P95 A-1, A-2, A-3, A-4

Mazda

MES CG 310

Toyota

TSH 6526G

Chrysler

PS 8956 E

General Motors

GM6280

GMW 3200

Delphi Automotive

DX 550108

DX 550073